SMT processing

SMT processing is a series of process technology for processing on the basis of PCB. It has the advantages of high mounting accuracy and fast speed, so it has been adopted by many electronic manufacturers. The SMT chip processing process mainly includes silk screen or glue dispensing, mounting or curing, reflow soldering, cleaning, testing, rework, etc. Multiple processes are carried out in an orderly manner to complete the entire chip processing process.

1.Screen printing

The front-end equipment located in the SMT production line is a screen printing machine, whose main function is to print solder paste or patch glue onto the pads of the PCB to prepare for the soldering of components.

2. Dispensing

The equipment located at the front end of the SMT production line or behind the inspection machine is a glue dispenser. Its main function is to drop glue onto the fixed position of the PCB, and the purpose is to fix the components on the PCB.

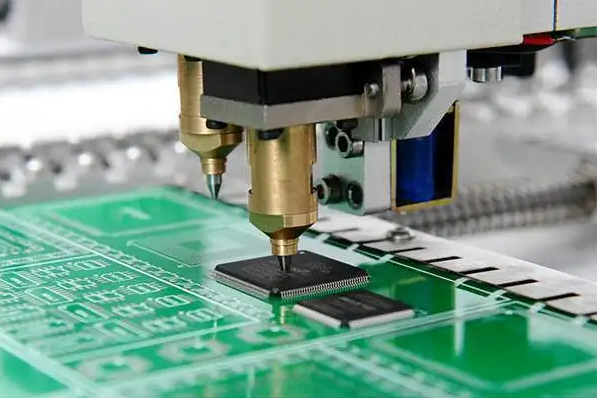

3. Placement

The equipment behind the silk screen printing machine in the SMT production line is a placement machine, which is used to accurately mount surface mount components to a fixed position on the PCB.

4. Curing

The equipment behind the placement machine in the SMT production line is a curing furnace, whose main function is to melt the placement glue, so that the surface mount components and the PCB board are firmly bonded together.

5. Reflow soldering

The equipment behind the placement machine in the SMT production line is a reflow oven, whose main function is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together.

6. Detection

In order to ensure that the soldering quality and assembly quality of the assembled PCB board meet the factory requirements, magnifying glasses, microscopes, in-circuit testers (ICT), flying probe testers, automatic optical inspection (AOI), X-RAY inspection systems and other equipment are required. The main function is to detect whether the PCB board has defects such as virtual soldering, missing soldering, and cracks.

7. Cleaning

There may be soldering residues harmful to the human body such as flux on the assembled PCB board, which need to be cleaned with a cleaning machine.