How to identify the quality of PCB circuit boards?

There are many types of PCB circuit boards on the market, and it is difficult to distinguish between good and bad quality. In this regard, here are a few ways to identify the quality of PCB circuit boards.

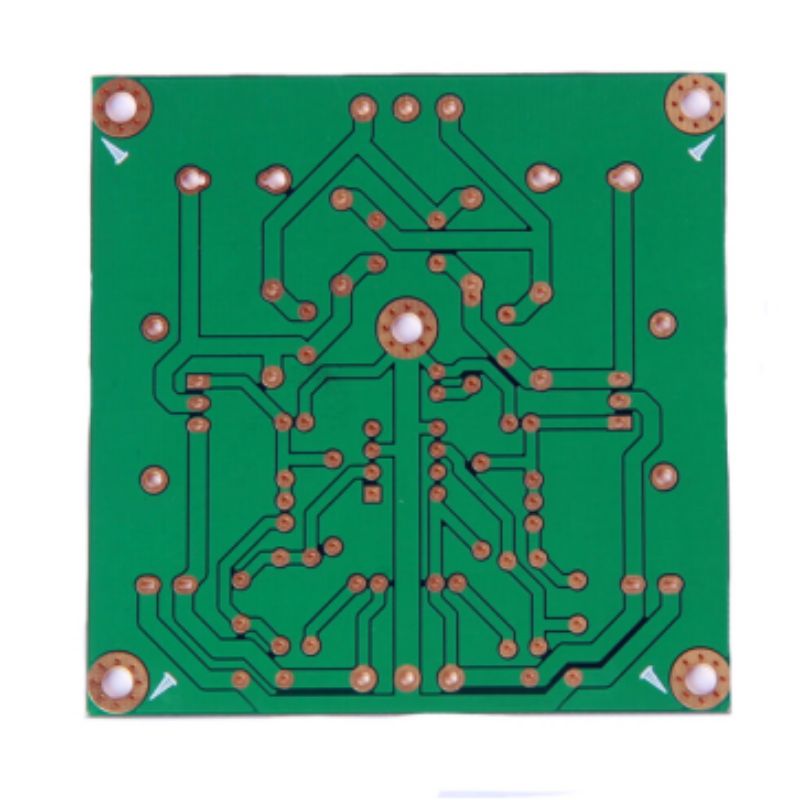

Judging from appearance

1. Appearance of weld seam

Since there are many parts on the PCB circuit board, if the welding is not good, the circuit board parts will easily fall off, seriously affecting the welding quality and appearance of the circuit board, so it is very important to have firm welding.

2. Standard rules for size and thickness

Since PCB circuit boards have different thicknesses compared to standard circuit boards, users can measure and check according to their own needs.

3. Light and color

Usually the external PCB circuit board is covered with ink for insulation. If the color of the board is not bright and there is less ink, it means that the insulation board itself is not good.

Judgment from the plate material

1. Ordinary HB cardboard is cheap and easy to deform and break. It can only be made into a single panel. The component surface is dark yellow in color and has an irritating smell. The copper coating is rough and thin.

2. Single-sided 94V0 and CEM-1 boards are relatively more expensive than cardboard. The color of the component surface is light yellow. They are mainly used for industrial boards and power boards with fire protection requirements.

3. Fiberglass board has higher cost, good strength, and is green on both sides. Basically, most PCB circuit boards are made of this material. The copper coating can be very precise and fine, but the unit board is relatively heavy. No matter what color of ink is printed on the PCB circuit board, it must be smooth and flat, and there should be no false lines, exposed copper or bubbling.