Procedure and precautions for double-sided circuit board welding

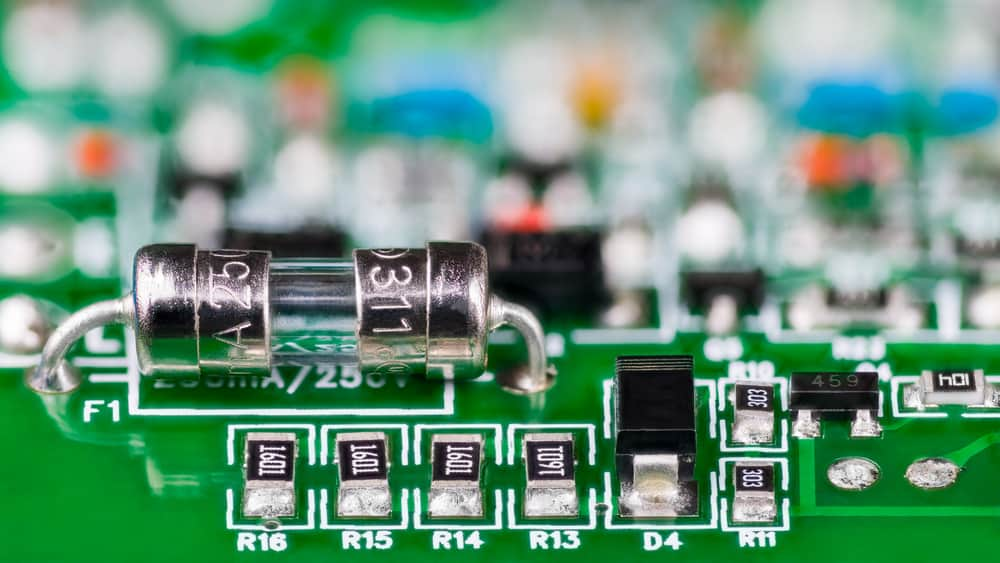

In the welding of two-layer circuit board, it is easy to have the problem of adhesion or virtual welding. And because of the increase of dual-layer circuit board components, each type of components for welding requirements welding temperature and so on are not the same, which also leads to the increase in the difficulty of welding dual-layer circuit board, including welding order in some products have strict requirements.

Procedure for double-sided circuit board welding:

Prepare tools and materials, including circuit boards, components, solder, solder paste, and soldering iron.

Clean the board surface and component pins: Clean the board surface and component pins with detergent or alcohol to ensure welding quality and reliability.

Place components: Place components on the circuit board according to the design requirements of the circuit board, paying attention to the direction and position of the components.

Apply solder paste: Apply solder paste to the pad on the component pins and circuit board in preparation for welding.

Welding components: Use electric soldering iron to weld components, pay attention to maintain a stable temperature and time, avoid excessive heating or welding time is too long.

Check the welding quality: check whether the welding point is firm and full, and there is no virtual welding, leakage welding and other phenomena.

Repair or rewelding: For welding points with welding defects, repair or rewelding is required to ensure welding quality and reliability.

Circuit board welding tip 1:

The selective welding process includes: flux spraying, circuit board preheating, dip welding and drag welding. Flux coating process The flux coating process plays an important role in selective welding.

At the end of welding heating and welding, the flux should be sufficiently active to prevent the generation of Bridges and prevent the oxidation of the circuit board. Flux spraying The board is carried by the X/Y manipulator over the flux nozzle, and the flux is sprayed onto the pcb board welding position.

Circuit board welding tip 2:

For microwave peak selective welding after reflow soldering process, it is important that the flux is accurately sprayed and the microporous spray type will not stain the area outside the solder joint.

The spot diameter of the micro-spot spraying flux is greater than 2mm, so the position accuracy of the flux deposited on the circuit board is ±0.5mm, so as to ensure that the flux is always covered on the welding part.

Circuit board welding tip 3:

The process characteristics of selective welding can be understood by comparing with wave soldering, the obvious difference between the two is that the lower part of the circuit board in wave welding is completely immersed in the liquid solder, while in selective welding, only some specific areas are in contact with the solder wave.

Since the circuit board itself is a poor heat transfer medium, it will not heat and melt the solder joints in the area adjacent to the components and circuit board when welding.

The flux must also be pre-coated before welding, and compared with wave soldering, the flux is only coated on the lower part of the board to be welded, rather than the entire pcb board.

In addition, selective welding is only applicable to the welding of plug-in components, selective welding is a new method, and a thorough understanding of the selective welding process and equipment is necessary for successful welding.

Double-sided circuit board welding needs to be carried out in accordance with the specified operating steps, pay attention to safety and quality control, and ensure welding quality and reliability.

Double-sided circuit board welding needs to pay attention to the following matters:

Before welding, clean the circuit board surface and component pins to ensure welding quality and reliability.

According to the design requirements of the circuit board, select the appropriate welding tools and materials, such as solder, solder paste, etc.

Before welding, take ESD measures, such as wearing ESD rings, to prevent electrostatic damage to the components.

Maintain a stable temperature and time during the welding process to avoid excessive heating or too long welding time, so as not to damage the circuit board or components.

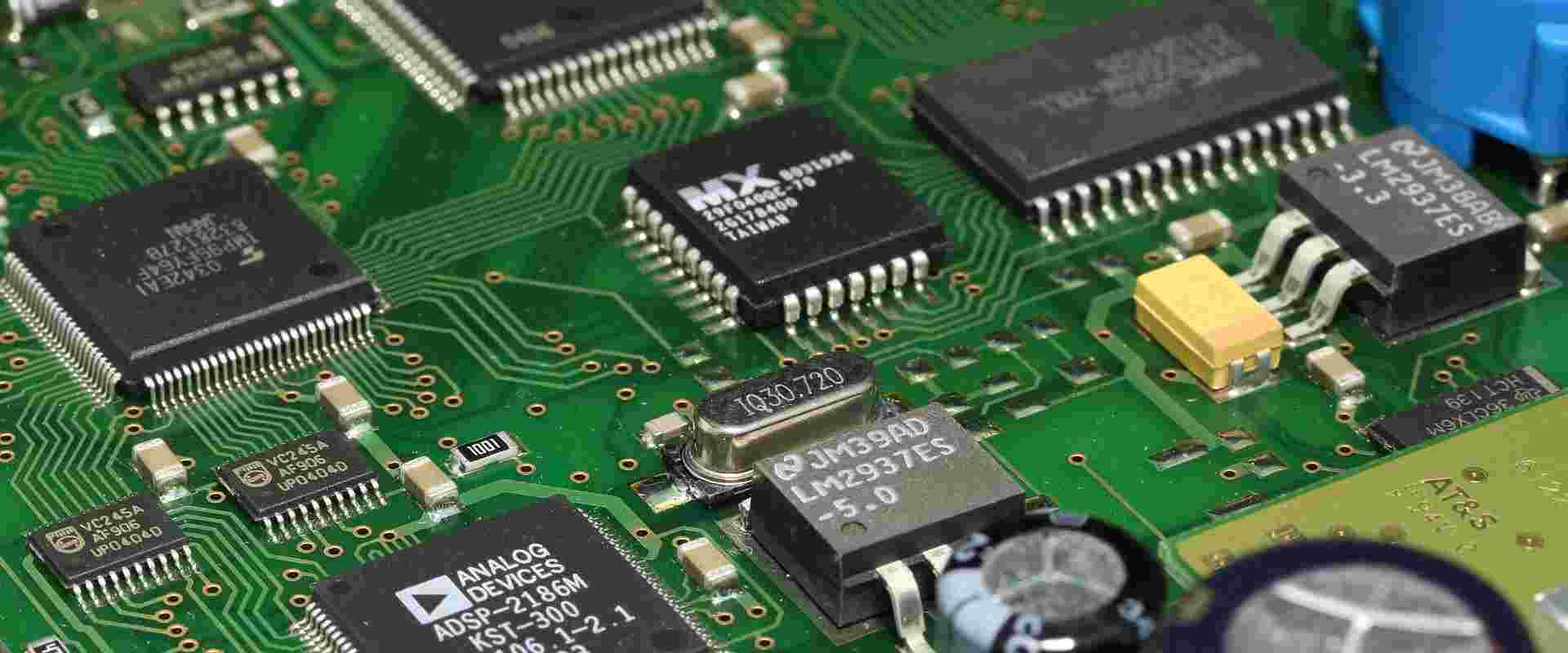

The welding process is generally carried out in accordance with the order of the equipment from low to high and from small to large. Priority is given to welding integrated circuit chips.

After the welding is completed, check the welding quality and reliability. If there are any defects, repair or re-weld in time.

In the actual welding operation, the welding of the double-sided circuit board needs to strictly comply with the relevant process specifications and operational requirements to ensure the quality and reliability of welding, while paying attention to safe operation to avoid harm to itself and the surrounding environment.