How to find the blind hole in the PCB board?

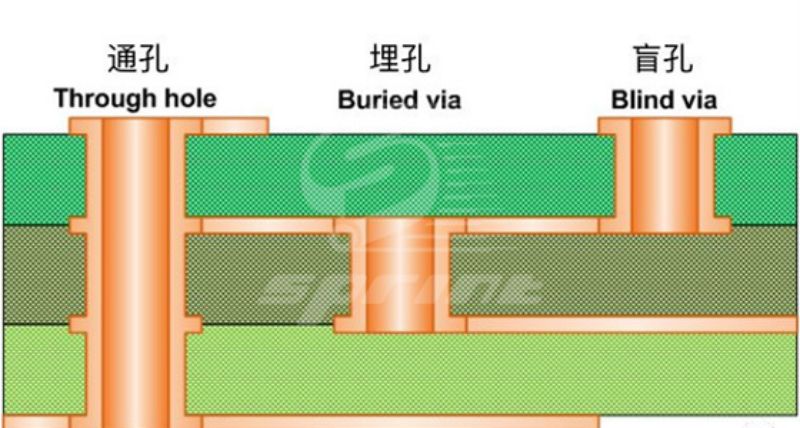

How to find the blind hole in the PCB board? In the field of electronics manufacturing, PCB (Printed Circuit Board, printed circuit board) plays a vital role, they connect and support a variety of electronic components, so that electronic devices work properly. Blind holes are a common design element in PCB manufacturing to connect circuits at different levels, but they are often difficult to find and check. This article will describe how to effectively find blind holes in PCB boards to ensure the quality and reliability of the board.

1. Use optical inspection methods

How to find the blind hole in the PCB board? Optical inspection is a common method used to find blind holes in PCB boards. By using a high-resolution microscope, technicians can look closely at the PCB surface for possible holes. To enhance the observation, a special light source, such as ultraviolet light, can be used to help identify the location of the blind hole.

In addition, digital microscopes and high-resolution cameras can be used to store observations in digital form for subsequent analysis and recording. This method is suitable for small batch production and research and development phases, but can become time-consuming and laborious in large-scale production.

2. Use X-ray detection

X-ray inspection is a very powerful method that can be used to find blind buried holes in PCB boards. It detects the location of the blind hole by illuminating the PCB board and capturing the reflected X-ray image. Because of the X-ray penetration, it is possible to detect deeper holes rather than just the surface.

X-ray inspection is highly characteristic and suitable for large-scale production environment. However, it requires equipment and training of experienced operators, so there may be some limitations in terms of cost and technical requirements.

3. Use heat detection technology

Thermal detection technology is a method of using heat sensitive detectors to find blind buried holes in PCB boards. In this method, the presence of blind burnings can be detected by placing a heat source on one side of the PCB board and monitoring the temperature change on the other side. Because blind burials affect heat conduction, they show different temperature responses during detection.

How to find the blind hole in the PCB board? Choosing the right method depends on production scale, budget and technical requirements. No matter which method is used, it is necessary to ensure the quality and reliability of the PCB board to meet the requirements of electronic equipment. In the PCB manufacturing process, the effective search of blind holes is crucial to ensure the quality and reliability of the circuit board.