Electroplated Hole Sealing/Filling On Ceramic PCB

Electroplated hole sealing is a common printed circuit board manufacturing process used to fill and seal through holes (through-holes) to enhance electrical conductivity and protection. In the printed circuit board manufacturing process, a pass-through hole is a channel used to connect different circuit layers. The purpose of electroplating sealing is to make the inner wall of the through hole full of conductive substances by forming a layer of metal or conductive material deposition inside the through hole, thereby enhancing the electrical conductivity and providing a better sealing effect.

1.the circuit board electroplating sealing process has brought many advantages in the product manufacturing process:

a)Improve circuit reliability: circuit board electroplating sealing process can effectively close holes and prevent electrical short circuit between metal layers on the circuit board. This helps improve the reliability and stability of the board and reduces the risk of circuit failure and damage

b)Enhance circuit performance: Through the electroplating sealing process, better circuit connection and electrical conductivity can be achieved. Electroplate filling hole can provide a more stable and reliable circuit connection, reduce the problem of signal loss and impedance mismatch, and thus improve the circuit performance ability and productivity.

c)Improve welding quality: circuit board electroplating sealing process can also improve welding quality. The sealing process can create a flat, smooth surface inside the hole, providing a better basis for welding. This can improve the reliability and strength of welding and reduce the occurrence of welding defects and cold welding problems.

d)Strengthen mechanical strength: The electroplating sealing process can improve the mechanical strength and durability of the circuit board. Filling holes can increase the thickness and robustness of the circuit board, improve its resistance to bending and vibration, and reduce the risk of mechanical damage and breakage during use.

e)Easy assembly and installation: circuit board electroplating sealing process can make the assembly and installation process more convenient and efficient. Filling holes provides a more stable surface and connection points, making assembly installation easier and more accurate. In addition, electroplated hole sealing provides better protection and reduces damage and loss of components during installation.

In general, the circuit board electroplating sealing process can improve circuit reliability, enhance circuit performance, improve welding quality, strengthen mechanical strength, and facilitate assembly and installation. These advantages can significantly improve product quality and reliability, while reducing risk and cost in the manufacturing process

2.Although the circuit board electroplating sealing process has many advantages, there are also some potential dangers or shortcomings, including the following:

f)Increased costs: The board plating hole sealing process requires additional processes and materials, such as filling materials and chemicals used in the plating process. This can increase manufacturing costs and have an impact on the overall economics of the product

g)Long-term reliability: Although the electroplating sealing process can improve the reliability of the circuit board, in the case of long-term use and environmental changes, the filling material and the coating may be affected by factors such as thermal expansion and cold contraction, humidity, corrosion and so on. This can lead to loose filler material, falling off, or damage to the plating, reducing the reliability of the board

h)3Process complexity: The circuit board electroplating sealing process is more complex than the conventional process. It involves the control of many steps and parameters such as hole preparation, filling material selection and construction, electroplating process control, etc. This may require higher process skills and equipment to ensure process accuracy and stability.

i)Increase the process: increase the sealing process, and increase the blocking film for slightly larger holes to ensure the sealing effect. After sealing the hole, it is necessary to shovel copper, grinding, polishing and other steps to ensure the flatness of the sealing surface.

j)Environmental impact: The chemicals used in the electroplating sealing process may have a certain impact on the environment. For example, wastewater and liquid waste may be generated during electroplating, which requires proper treatment and treatment. In addition, there may be environmentally harmful components in the filling materials that need to be properly managed and disposed of.

When considering the circuit board electroplating sealing process, it is necessary to comprehensively consider these potential dangers or shortcomings, and weigh the pros and cons according to specific needs and application scenarios. When implementing the process, appropriate quality control and environmental management measures are essential to ensure the best process results and product reliability.

3.Acceptance standards

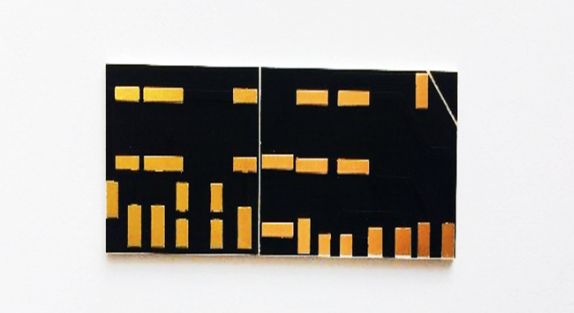

According to the standard: IPC-600-J3.3.20: Electroplated copper plug microconduction (blind and buried)

Sag and bulge: The requirements of the bulge (bump) and depression (pit) of the blind micro-through hole shall be determined by the supply and demand parties through negotiation, and there is no requirement of the bulge and depression of the busy micro-through hole of copper. Specific customer procurement documents or customer standards as the basis for judgment.