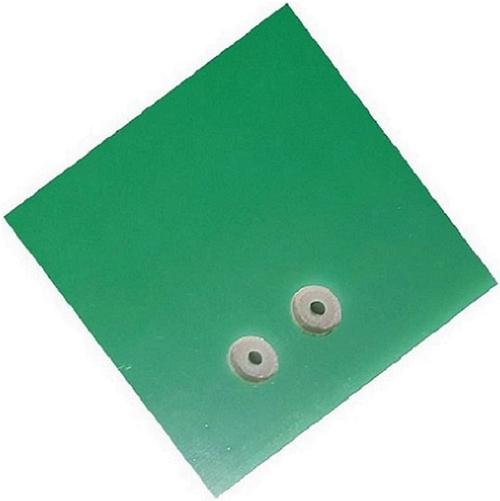

Countersunk holes are drilled on the circuit board with a flat head drill needle or gong knife, but cannot be drilled through (i.e., semi through holes). The transition part between the hole wall at the outermost/largest hole diameter and the hole wall at the smallest hole diameter is parallel to the pcb surface. The part connecting the large and small holes is a plane, not an inclined plane.

Counterbore is mostly used for metal circuit boards, such as aluminum substrate and copper substrate. The metal substrate has high mechanical strength and is not easy to damage the PCB structure.

The through-hole, as the name implies, is also a through-hole, which can pass through objects or liquids of appropriate size,

The function is:

a. It is used for connection and can be made into threaded through-hole.

b. Make cylinders for piston engines.

c. In life, the clothes and pants we wear are also examples of through-hole applications

The general crimping hole is a copper plated plug-in hole.

Because of the special design of the element foot, it can be firmly connected with the hole by its structural tension after being inserted into the hole.

The advantage is to reduce a wave soldering set for welding such components; If such holes are not welded in the end, it will be easier to replace the parts. Of course, repeated replacement will affect the reliability of the hole.

The element pins requiring crimping holes are generally provided with expansion function, rather than thread function.

Some components will be welded again later when other components are welded, while others will not be welded.

Counterbore is divided into three names:

1. Fully sink the head of the fastener into the step hole of the part, called counterbore

2. The head of the fastener is not completely sunk into the step hole of the part, which is called countersink

3. The head of the fastener will not sink into the part basically, and only the hole with the flat surface of the part is called fishhole

The difference between countersunk hole and countersunk hole is that the upper part of the bolt hole is reamed: the countersunk hole is a straight cylinder structure; The countersunk hole is a 45 degree structure, which is smoother than the countersunk hole.

The upper reaming of the bolt hole can accommodate the bolt head, so that the bolt head is not higher than the surrounding surface.