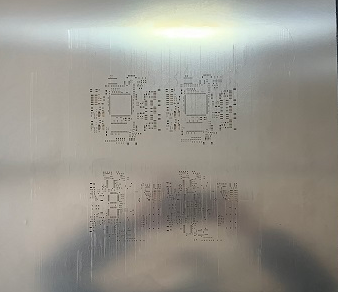

Analysis of three kinds of PCB stencil technology

According to the process, the pcb stencil can be divided into the following categories:

1. Solder paste stencil: As the name suggests, it is used to brush solder paste. Carve holes in a piece of steel that correspond to the pads of the pcb board. Then use solder paste to pad to the PCB board through the stencil. When printing solder paste, apply the solder paste on the top of the stencil, while the circuit board is placed under the stencil, and then use a scraper to scrape the solder paste evenly on the stencil holes (the solder paste will be squeezed from the steel mesh. flow down the mesh and cover the circuit board). Paste the SMD components, and reflow soldering can be done uniformly, and the plug-in components are manually soldered.

2. Red plastic stencil: The opening is opened between the two pads of the component according to the size and type of the part. Use dispensing (dispensing is to use compressed air to point the red glue to the substrate through a special dispensing head) to point the red glue to the PCB board through the steel mesh. Then mark the components, and after the components are firmly attached to the PCB, plug in the plug-in components and pass the wave soldering together.

3. Dual-process stencil: When a PCB needs to be brushed with solder paste and red glue, then a dual-process stencil needs to be used. The dual-process stencil is composed of two stencils, one ordinary laser stencil and one stepped stencil. How to determine whether to use stepped stencil or red glue for solder paste? First understand whether to brush solder paste or red glue first. If the solder paste is applied first, then the solder paste stencil is made into an ordinary laser stencil, and the red glue stencil is made into a stepped stencil. If the red glue is applied first, then the red glue stencil is made into an ordinary laser stencil, and the solder paste stencil is made into a stepped stencil.