Fastline could produce 1- 50 layers PCB board for electronic products.providing PCB design, PCB fabrication,PCB clone and PCB assembly services. and we have got the UL, ISO, SGS certifications.

Pls see our pcb catalog below:

1. single side pcb

2. double side pcb

3. Multilayer pcb(3-26+ layers)

4. Flexible PCB(FPC)

5. Rigid-flex PCB board

6. Aluminum PCB board for LED(1-4 layers)

7. MCPCB board (1-4 layers)

8.Ceramic PCB(1-4 layers)

9. HDI pcb board

10. High frequency PCB

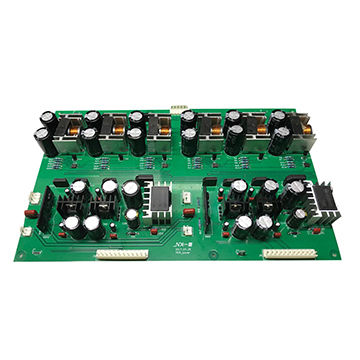

11. PCB assembly

| PCB Manufacture Capability | |

| Item | Manufacture Capability |

| Layers | 1-26 Layers |

| HDI | 2+N+2 |

| Material Types | Fr-4, Fr-5, High-Tg, Aluminum Based , Halogen Free, |

| Isola, Taconic, Arlon, Teflon, Rogers, | |

| Max. Panel Dimension | 39000mil * 47000mil (1000mm * 1200mm) |

| Outline Tolerance | ± 4mil (± 0.10mm) |

| Board Thickness | 8mil-236mil (0.2 - 6.0mm) |

| Board Thickness Tolerance | ± 10% |

| Dielectric Thickness | 3mil-8mil ( 0.075mm-0.20mm) |

| Min. Track Width | 3mil ( 0.075mm ) |

| Min. Track Space | 3mil ( 0.075mm ) |

| External Cu Thickness | 0.5 OZ - 10 OZ ( 17um - 350um) |

| Internal Cu Thickness | 0.5OZ - 6OZ ( 17um - 210um) |

| Drilling Bit Size ( CNC ) | 6mil-256mil ( 0.15mm - 6.50mm) |

| Finished Hole Dimension | 4mil-236mil(0.1mm - 6.0mm) |

| Hole Tolerance | ± 2mil (± 0.05mm) |

| Laser Drilling Hole Size | 4mil(0.1mm) |

| Aspect Ration | 16: 1 |

| Solder Mask | Green, Blue, White, Black, Red, Yellow, Purple, etc. |

| Min Solder mask Bridge | 2mil(0.050mm) |

| Plugged Hole Diameter | 8mil-20mil ( 0.20mm-0.50mm) |

| Beveling | 30o - 45o |

| V-scoring | +/-0.1mm, 15o 30o 45o 60o |

| Impedance Control | Min. 5% General ± 10% |

| Surface Finishing | HASL, HASL(lead Free), Immersion Gold |

| Immersion Silver, OSP, Hard Gold ( up to 100u” ) | |

| Certification | UL RoHS ISO9001: 2000 ISO14000: 2004 SGS |

| Testing | Flying probe, E-TEST, X-RAY Inspection , AOI |

| Files | Gerber Protel DXP Auto CAD PADS OrCAD Express PCB etc |

PCB advantages:

1 R&D team support

2 UL, RoHS,ISO9001,SGS

3.IPC class2

4.Advanced production line and promtly delivery.

5,Honest Credibility in China.

6.Professional and abundant experience in PCB.

7.Competitive price and good quality.

8. Excellent after-sales service.

Trade Terms:

1. We have no MOQ.

2. Payment Term:T/T or Western Union.

3. Delivery ways:UPS,FEDEX,DHL etc,door to door service by sea or air etc.

Application:

1. Consumer electronics.

2. Industrial control.

3. medical instrument.

4. fire service implement etc.

Our Service:

1.Reply your enquiry in 2 working hours.

2.Experienced staffs answer all your questions in fluent English.

3.Customized design is avaliable OEM&ODM are welcomed.

4. Exclusive and unique solution can be provide to our customer by our well-trained and professional engineers and staffs.

5. Special discount and protection of sales area provided to our distributor.

| PCB Prototype Lead Time: | ||

| Item | General time | Quick Turn |

| 1-2 | 4 days | 1 days |

| 4-6 Layers | 6 days | 2 days |

| 8-10 Layers | 8 days | 3 days |

| 12-16 Layers | 12 days | 4days |

| 18-20 Layers | 14 days | 5 days |

| 22-26 Layers | 16 days | 6 days |

| Note: Base on all data received by us and must be complete and problem free, Lead time is ready to ship time. | ||

FAQ

Q1: Are you a factory or trade company?

A1: We have our own PCB manufacturing & Assembly factory.

Q2: What’s your minimum order quantity?

A2: Our MOQ is not the same based on different items. Small orders are also welcome.

Q3: what file we should offer?

A3: PCB:Gerber file is better,( Protel,power pcb,PADs file), PCBA : Gerber file and BOM list.

Q4: No PCB file/GBR file, only have the PCB sample, can you produce it for me?

A4: Yes, we could help you to clone the PCB. Just send the sample PCB to us, we could clone the PCB design and work out it.

Q5: What any other information should be offered except for file?

A5:Following specifications are needed for quotation:

a) Bese material ; b) Board thickness ; c) Copper thickness ; d) Surface treatment; e) Color of soldermask and silkscreen; f) Quantity