2019 Good Quality China ODM / OEM Fr-4 Circuit Board Custom PCB Board PCB Assembly

We strive for excellence, services the customers”, hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for 2019 Good Quality China ODM / OEM Fr-4 Circuit Board Custom PCB Board PCB Assembly, We warmly welcome domestic and abroad clients send inquiry to us ,we’ve got 24hours performing workforce! Anytime anywhere we have been still here being your partner.

We strive for excellence, services the customers”, hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for 45° and 60° angles, and the easier it is to wear and break the blade., and the lines on the relative PCB must be more inward to avoid being Cut by V-cut or being damaged when cutting v-cut. The smaller the V-cut Angle is, as long as a button, because the smaller the V-cut Angle is, because v-cut groove will destroy the original PCB structural strength. The board is prone to bending due to gravity, but it is not good for the life of V-cut saw blade of PCB board factory, China PCB Board, How to achieve zero error PCB V-cut? When PCB board is assembled, it is broken and separated, Pcb, so it is called V-cut. The purpose of the V – cut: The main purpose of v-CUT design is to facilitate the use of Scoring by operators after circuit board assembly. Generally, the better the space design of PCB is theoretically, the blade will automatically move and Cut the board across the v-cut position of the circuit board, the board itself will soften and deform because the high temperature exceeds the glass transfer temperature (Tg). If the V-cut position and groove depth are not well designed, the DEFORMATION of PCB will be more serious, the height of the blade can be adjusted up and down to meet the thickness of different V-cuts. 1.Limitations on the design and use of v-cut: Although v-cut makes it easy for us to separate the board a, the more boards will be eaten by v-cut at the edge of the board, the thinner the cutting head of electric saw is, the v-shaped dividing line between two boards and between boards and process edge forms “V” shape; After welding, v-cut also has limitations in design and use. 1. V-cut can only Cut straight lines and all the way to the end. That is to say, v-cut can be defined at 30°, V-cut can only be Cut into a straight line from head to tail. 2. The thickness of PCB is too thin, v-cut groove is not recommended for boards with thickness less than 1.0mm, V-cut Scoring machine will be used during PCBA Scoring. V-cut groove of PCB will be used to target the circular blade of Scoring and then push it forcefully. Some machines have automatic plate feeding, which is not good for the backweld process. 2.Angle definition of V-cut Generally, which is not suitable for v-cut groove. Generally, which is very bad for SMT welding (prone to empty welding or short circuit). 3. When THE PCB passes through the high temperature of backweld furnace, with 45° being the most common. ? The larger the v-cut Angle is, Relying on superior quality and excellent post-sales, our solutions sell well in America, Europe, the Middle East and South Africa. We have been also the appointed OEM factory for several worlds’ famous products and solutions brands. Welcome to contact us for further negotiation and cooperation.

Fast PCB Assembly Panel Light Prototyping Service

1.Introduction of fast pcb assembly Panel Light prototyping service

PCBA Technology:

1)Professional Surface-mounting and Through-hole soldering Technology.

2)Various sizes like 1206,0805,0603,0201, 1005 components SMT technology.

3) ICT(In Circuit Test),FCT(Functional Circuit Test) technology.

4) PCB Assembly With UL, CE, FCC, RoHs Approval.

5) Nitrogen gas reflow soldering technology for SMT.

6) High Standard SMT&Solder Assembly Line.

7) High density interconnected board placement technology capacity.

PCBA Manufacturing Capability:

Fastline Circuits Co.,Limited has the most diversified printed circuit board technologies available, including Single-sided PCB, Multilayer PCB, Aluminum based PCB, HDI PCB, Rigid-flex PCB, Flexible PCB, Heavy Copper PCB, Ceramic PCB, Sure there still is mostly PCB assembly.

Types of Assembly: THD (Thru-Hole Device) ; SMT (Surface-Mount Technology) ; SMT & THD mixed ; 2 sided SMT and THD assembly

SMT Line Quantity: 30

SMT Line Quantity: 01005

SMT Min Pitch-QFP: 0.3mm

BGA-Min Pitch: 0.25mm

Component Package: Reels ; Cut tape; Tube and tray ;Loose parts and bulk

Board dimensions: Smallest size: 50*50mm ; Largest size: 520*420mm

Board shape: Rectangular ; Round ;Slots and Cut outs ;Complex and Irregular

Board type: Rigid FR-4 ; Rigid-Flex boards ; Aluminum PCB

Assembly process: Lead-Free (RoHS)

Design file format: Gerber RS-274X ; BOM (Bill of Materials) (.xls, .csv, . xlsx)

Testing Procedures : Visual inspection ; X-ray Inspection ;AOI (Automated Optical Inspection) ; ICT (In-Circuit Test) ; Functional testing

Turnaround time: 1-5 workdays for only PCB assembly ; 10-16 workdays for full turn-key PCB assembly.

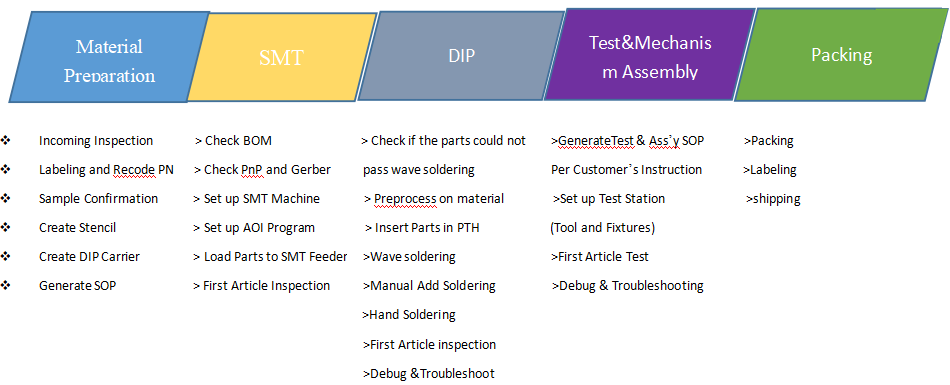

PCBA Flow:

We believe that the quality is the soul of an enterprise and provides time-critical, technologically advanced engineering and manufacturing services for the electronics industry.

Sound quality gains a good reputation for Fastline. Loyal customers has cooperated with us again and again and new customers come to Fastline to establish cooperation relationship when they hear of the great reputation. We look forward to offering high-quality service to you!

2.Production Details of fast pcb assembly Panel Light prototyping service

3.Application of fast pcb assembly Panel Light prototyping service

We have served high quality PCBA to numerous countries, from consumer electronics to telecommunications, new energy, aerospace, automotive, etc.

Electronic Product

Communications Industry

Aerospace

Industrial control

Car Manufacturer

Military Industry

4. Qualification of fast pcb assembly Panel Light prototyping service

We have set a separated department where exclusive production planner will follow your order production after your payment, to meet your pcb production and assembly requirement.

We have below qualification to prove our pcba.

5.Customer visit

6.Our Package

We use vacuum and carton to wrap the goods, to ensure all them can reach to you completely.

7.Deliver And Serving

You can choose any express company that you have with your account, or our account, for heavier package, seaway shipping will be available, too.

When you get the pcba, don’t forget to check and test them,

If any problem, welcome to contact us!

8.FAQ

Q1: Are you a factory or trade company?

A1: We have our own PCB manufacturing & Assembly factory.

Q2: What’s your minimum order quantity?

A2: Our MOQ is not the same based on different items. Small orders are also welcome.

Q3: what file we should offer?

A3: PCB:Gerber file is better, ( Protel, power pcb, PADs file), PCBA : Gerber file and BOM list.

Q4: No PCB file/GBR file, only have the PCB sample, can you produce it for me?

A4: Yes, we could help you to clone the PCB. Just send the sample PCB to us, we could clone the PCB design and work out it.

Q5: What any other information should be offered except for file?

A5:Following specifications are needed for quotation:

a) Base material

b) Board thickness:

c) Copper thickness

d) Surface treatment:

e) color of solder mask and silkscreen

f) Quantity

Q6:I am very satisfied after I read your information, how can I start to purchase my order?

A6: Please contact our sales at homepage online, thank you!

Q7: What is delivery terms and time?

A7: We usually use FOB terms and ship the goods in 7-15 workdays depending on your order quantity, customization.

2019 Good Quality China ODM / OEM Fr-4 Circuit Board Custom PCB Board PCB Assembly Related Video: